Rader has specialized in mercury removal and mercury spill cleanups for over 30 years. Our approach to mercury decontamination is the result of a long-standing interest in the science of elemental mercury. Depending on conditions, most mercury spills can be cleaned up with a mercury recovery vacuum.

Before determining how to clean up a mercury spill at your facility, a hazardous materials expert will visit your site with a Lumex 915 Plus Mercury Vapor Analyzer to determine the most effective way to decontaminate and remove elemental mercury from your facility.

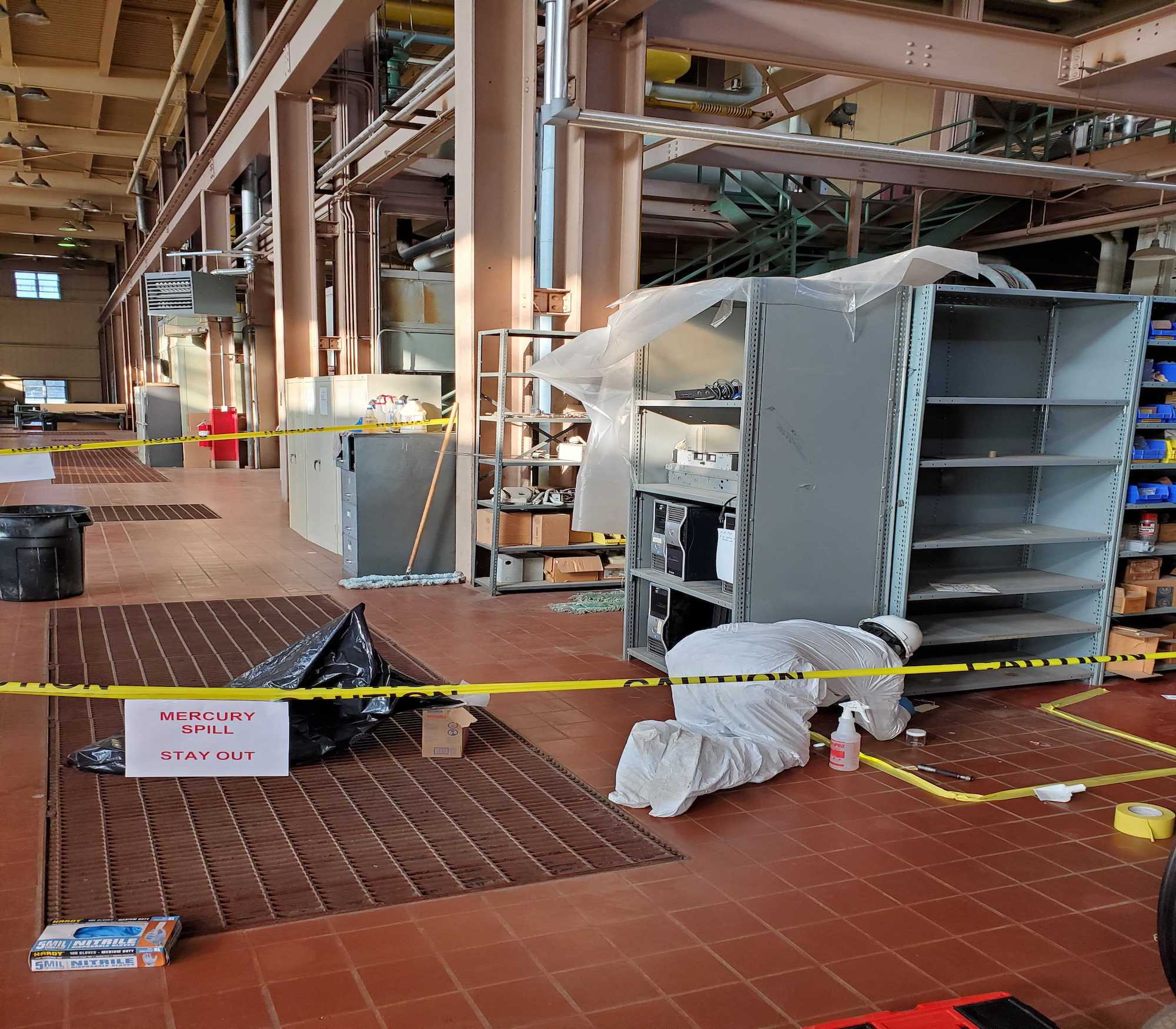

During the actual mercury removal phase of a project, Rader’s team of workers wear respirators equipped with mercury vapor cartridges and standard Level C Protection. All workers have both Hazardous Materials Worker Training and Mercury Awareness Training. In addition, all workers participate in a medical evaluation program.

Handling Microscopic Mercury Spills

In most cases, mercury can be remediated with a mercury recovery vacuum. But, this process could still leave behind microscopic and/or embedded mercury contamination. Mercury vapor continues to be released if any elemental mercury remains after the visible (unmagnified) mercury spill cleanup is completed. Rader understands this and has developed effective mercury spill cleanup methods that effectively clean both visible and microscopic mercury molecules.

Providing Proprietary Solutions to Mercury Spills

Chemists at Rader recognized in the early days of the company that all commercially available mercury vapor reduction compounds are basically suppressants that stop the release of mercury vapor. However, the suppressing effects may not last long and the only permanent solution may be to completely remove all microscopic traces of mercury.

With that in mind, we developed a procedure to remove elemental mercury, rendering suppressants obsolete. Key Clean and Rader Reducer are the chemicals that Rader developed to achieve this. These substances work by suspending the microscopic elemental mercury in a solution so that it can be collected using either a mercury vacuum, cloth rags or other media depending on the surface to be cleaned.

Key Clean and Rader Reducer, although integral to the process, cannot permanently remove elemental mercury. Knowledge of the substrate and its conditions are also important. Rader has the knowledge to recognize and address these conditions, allowing Rader’s solutions to work.

Mercury spills occur in many places and on many different surfaces. When elemental mercury droplets shatter, they adhere to surfaces both horizontal and vertical. They also make their way into cracks, crevices and anything else slightly porous. Cleaning spilled mercury from rough or smooth concrete is different than cleaning it from floor tile or steel. At the same time, floor tile or steel is different than cleaning mercury from hardwood floors.

Handling Mercury Spills in Industrial Settings

If the spill has occurred in an industrial setting and the contaminated surfaces are full of grease and grime, it may be necessary to address these contaminants at the same time the mercury is addressed. In addition to removing elemental mercury, Rader products don’t harm most surfaces, unlike the commercially available chemicals which may react with different metals and can be corrosive. Rader’s chemicals are even safe for aluminum and have been successfully used to decontaminate commercial aircraft.

Removing Mercury from Personal Belongings

Many times, a mercury spill will contaminate personal belongings that cannot be replaced. However, the Rader team has devised many different techniques to decontaminate and save your personal belongings. Certain porous items, however, such as shoes, carpeting, etc., are not easily cleaned. It is possible to launder some clothing items using our proprietary chemicals so that they can be safely worn again. Sometimes, it may be more prudent to replace items rather than decontaminate them. Our team has the experience to know the difference, thereby saving you time and money.

Handling Mercury Spills at Superfund Sites

In very large mercury spills/contamination situations, Rader offers a competitive advantage with its knowledge of laboratory analysis, waste characterization and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA). This institutional knowledge, combined with Rader’s proprietary chemicals and its vast mercury cleanup experience, demonstrates that the Rader Mercury Removal Method is one of the most effective in the hazardous waste disposal industry.